Outboard seat ribs have to be fluted to conform to the curve in the bottom skin. Done!

All the correct bolts lined up ready to attach the seat ribs to the aft center section bulkhead.

Bolting of those ribs in progress…

All happily bolted in place.

Seat ribs now fully riveted.

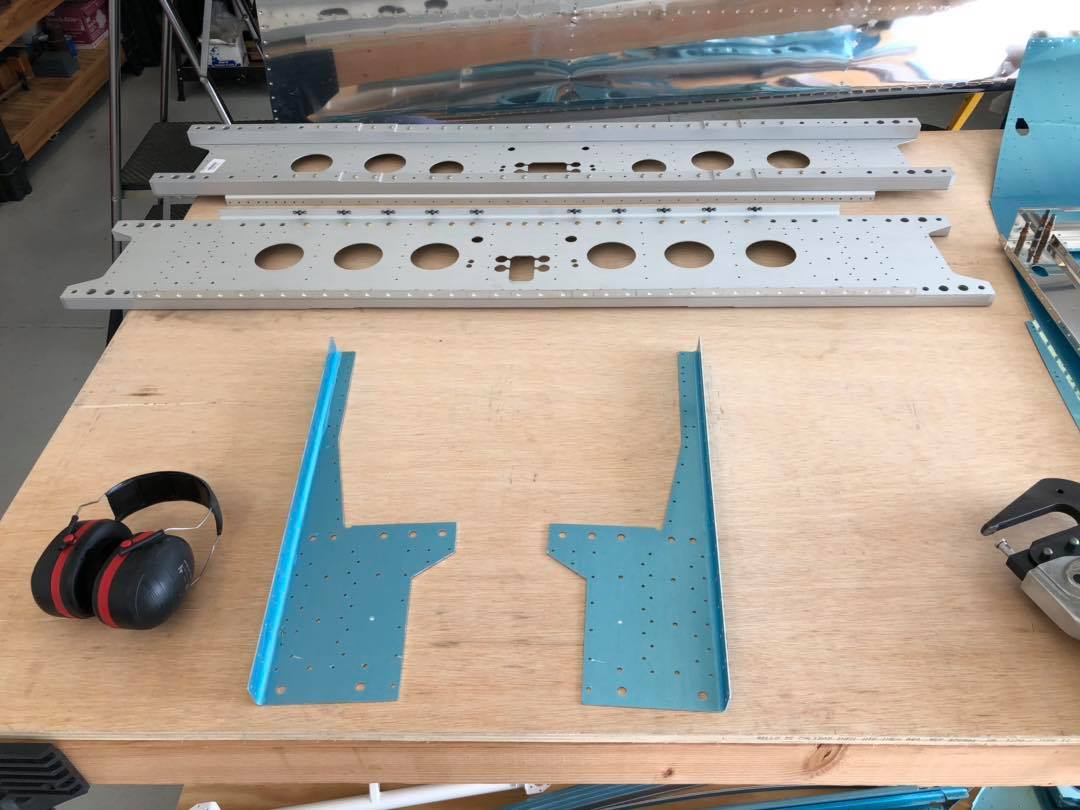

Baggage ribs and components ready for priming.

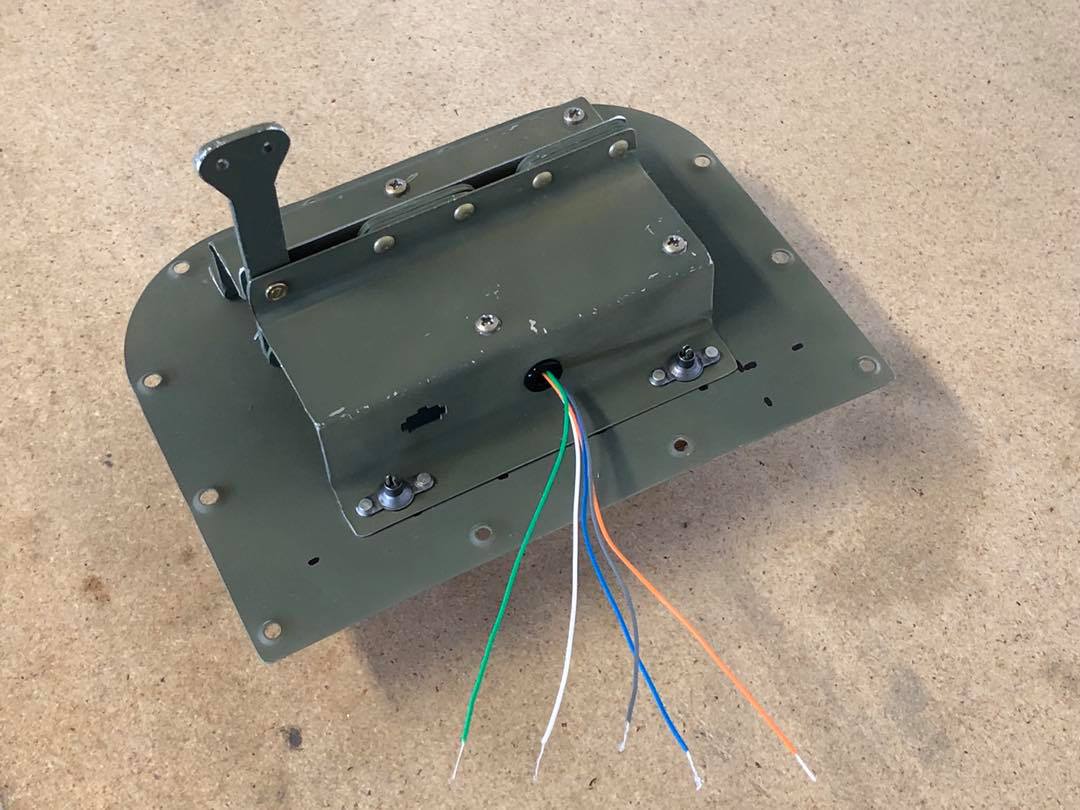

Bulkhead bottom channel clecoed to seat rib assembly.

Bulkhead bottom channel clecoed to seat rib assembly.

Bulkhead bottom channel riveting complete for now. The remaining seat ribs are riveted a bit later on.