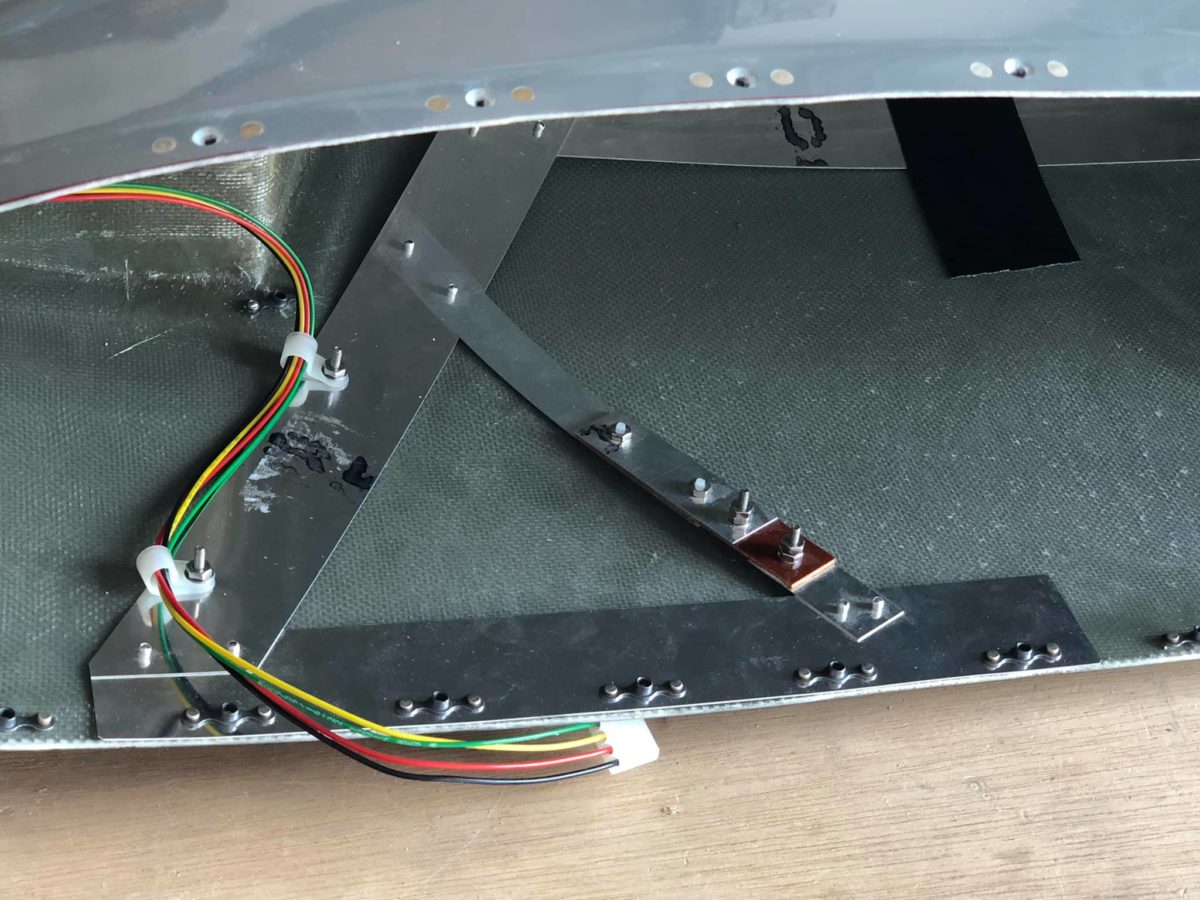

Archer antenna wired, secured, and ready for wingtip installation.

Nav light wires (with necessary extensions spliced in) and antenna cable ready for wingtip installation.

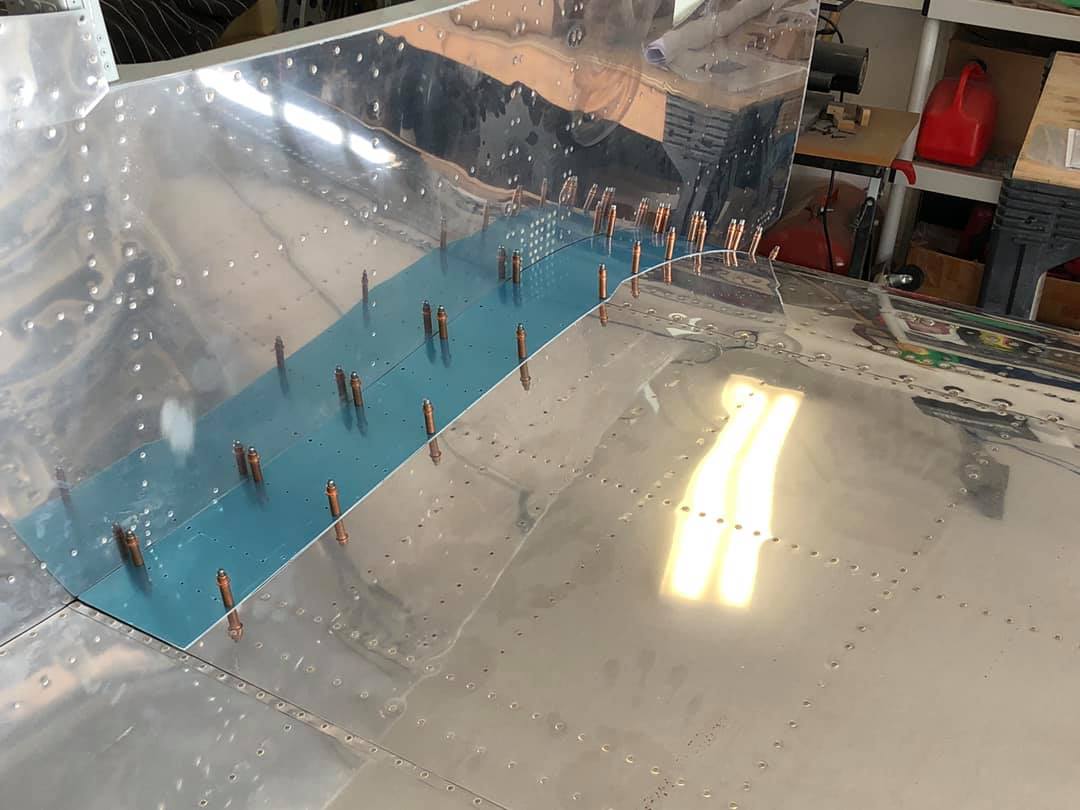

Right wingtip rib drilled and clecoed in place.

Right wingtip ready for installation.

Right wingtip wiring complete.

Right wingtip clecoed in place and ready for, ahem, screwing.

Right wingtip fully installed and ready for flight.