Rudder bottom fairing doubler drilled and clecoed in place.

Rudder bottom fairing doubler center hole cut.

Rudder bottom fairing doubler floxed and riveted in place.

Rudder bottom fairing doubler cleaned of squeezed out flox.

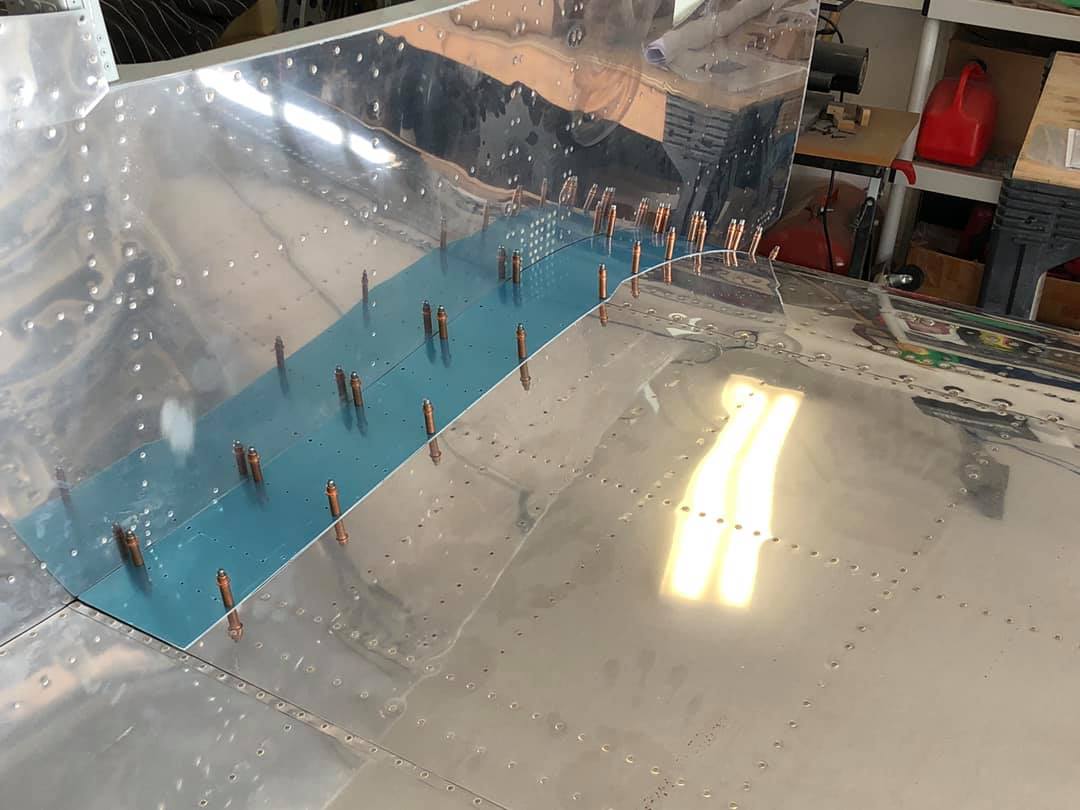

Rudder tip fairing drilled and clecoed in place.

Rudder tip fairing drilled up to final hole size.

Rudder tip fairing riveted in place and ready for flight!

Empennage fairing set in place for an initial fitting. It actually looks quite good – better than expected and much better than the last one I installed back in 2001.