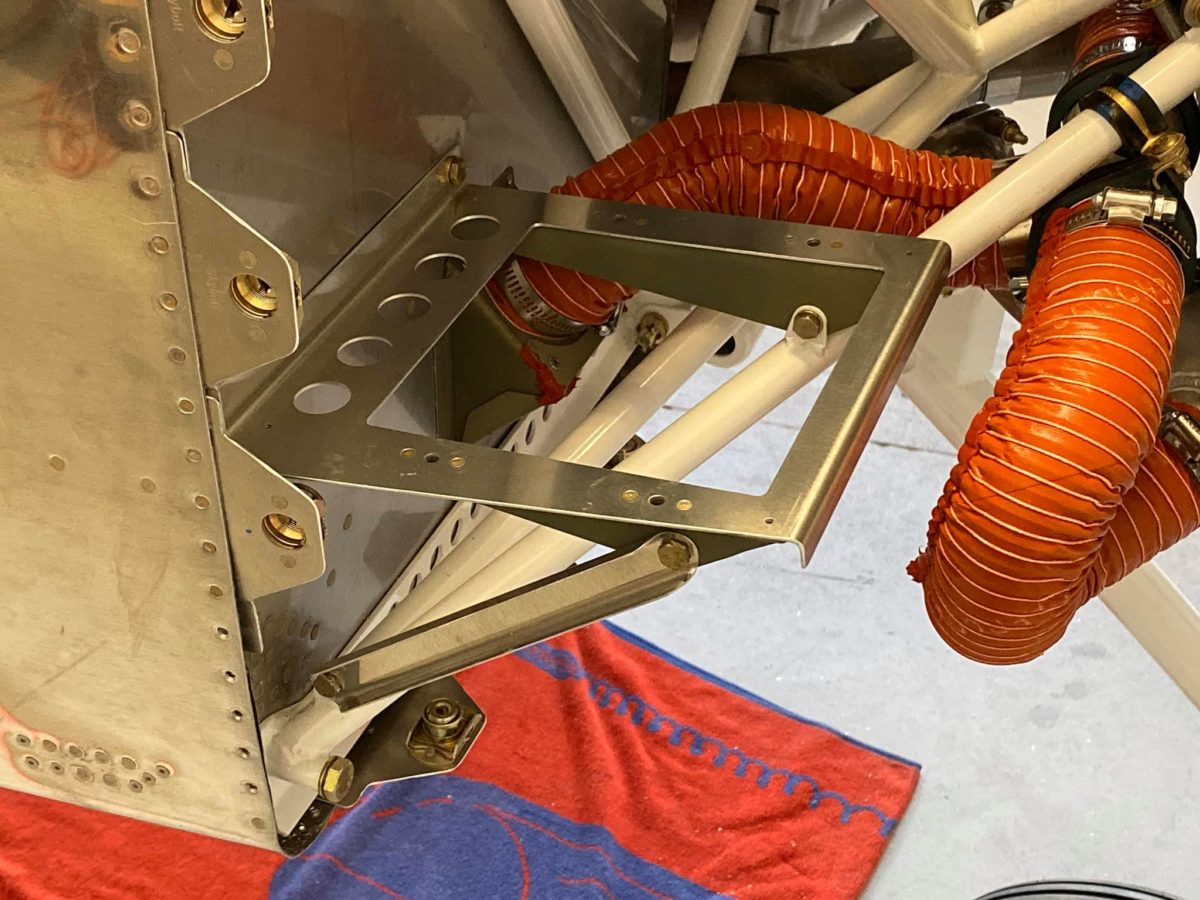

Oil cooler tray assembly ready for installation.

Yep, you’re right – there’s no way to put a wrench, socket, or other tightening implement on that bolt head without removing the lowest Camloc flange. I tried everything that came to mind, but eventually had to do just that.

Camloc flange removed, bolt tightened, and flange about to be replaced.

Oil cooler tray installed.

I just set the oil cooler in place to check that its flange holes lined up with the tray nutplates.

Oil cooler and inlet assembly installed.

Oil cooler lines installed along with oil pressure line.

Oil cooler lines installed along with oil pressure line.

The oil pressure line needs to have its Adel clamp replaced (a ‘tomorrow’ task!) due to the firesleeved Aircraft Specialty line being too large, diameter-wise, for the original clamp.

Looking down at the two oil cooler hose connections.