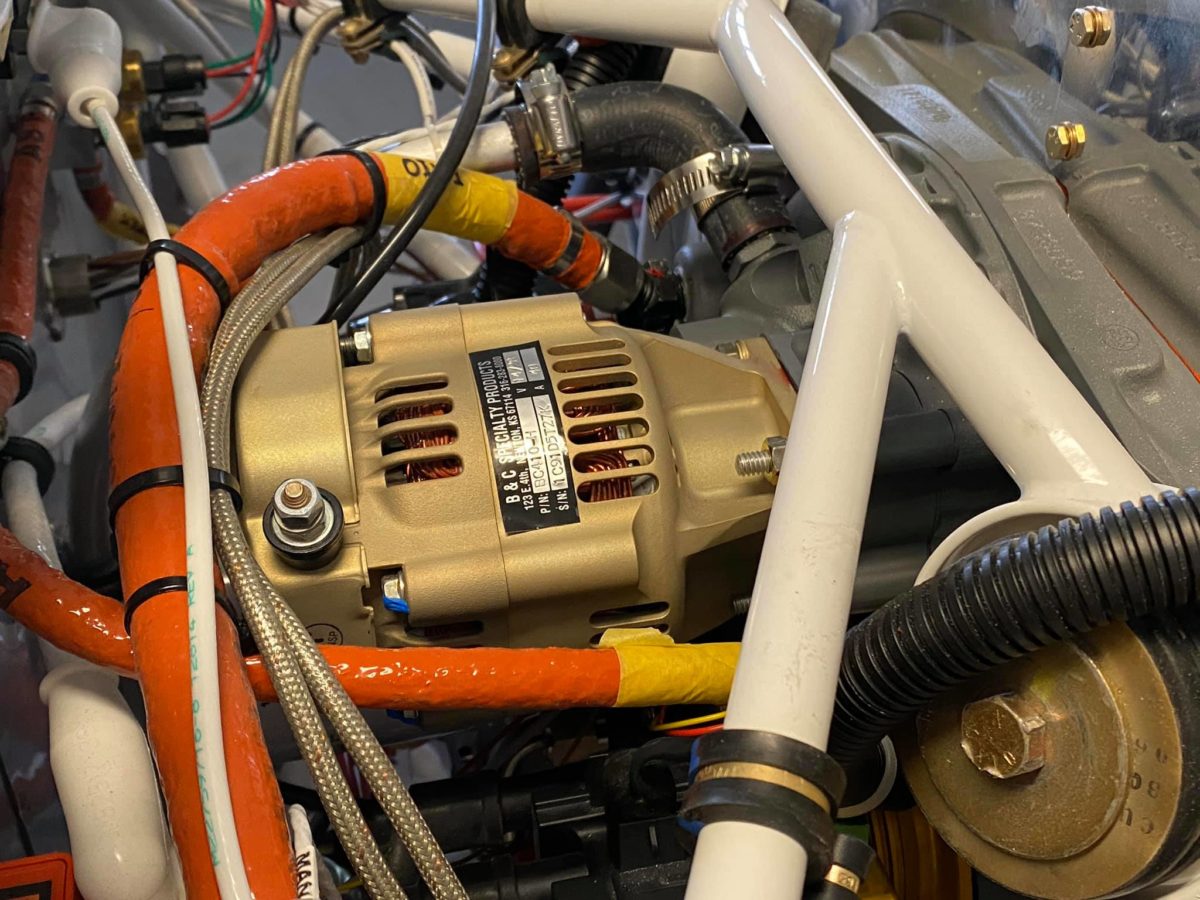

Backup alternator installed to the engine’s accessory pad. This is where, in ages past, our forebears (and me, too!) used to install a vacuum pump. Tight quarters, but everything fit eventually.

Backup alternator installed to the engine’s accessory pad. This is where, in ages past, our forebears (and me, too!) used to install a vacuum pump. Tight quarters, but everything fit eventually.

The time to install the backup alternator finally arrived this afternoon and, as expected, starting and torquing three of the four nuts was easy. Getting the fourth one started was a bear, but was eventually accomplished with a suggestion from Vic Syracuse (thanks!!) and some creative work by my wife with monofilament (don’t ask).

The question is how to properly torque that tough nut. This is the nut on the lower left, of course. What’s the secret?

I have the pictured wrench, but am not having any success with it. Is there another tool more suited to this particular situation?