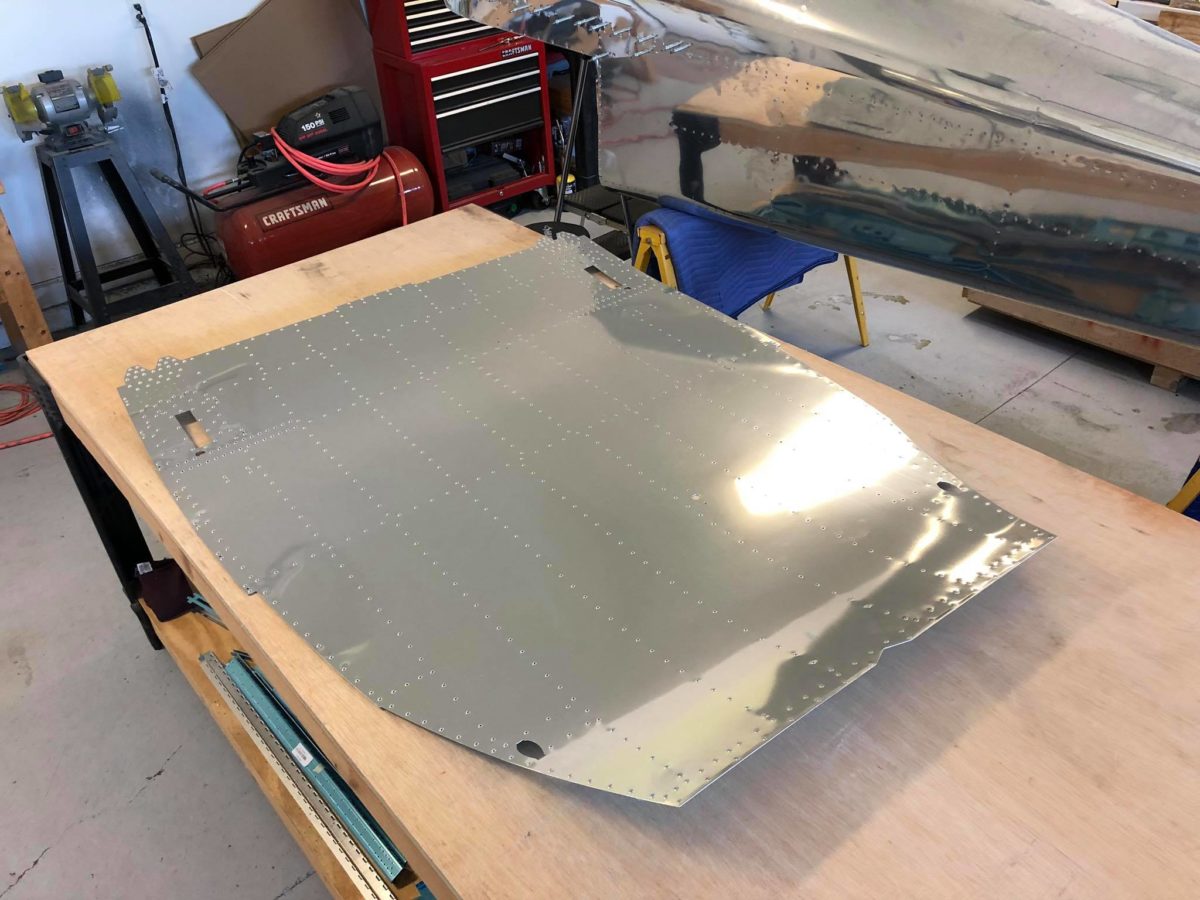

Cover panels and nutplates riveted.

Battery box priming underway.

Forward and mid fuselage lower structure overlap area primed.

Battery box riveted to firewall.

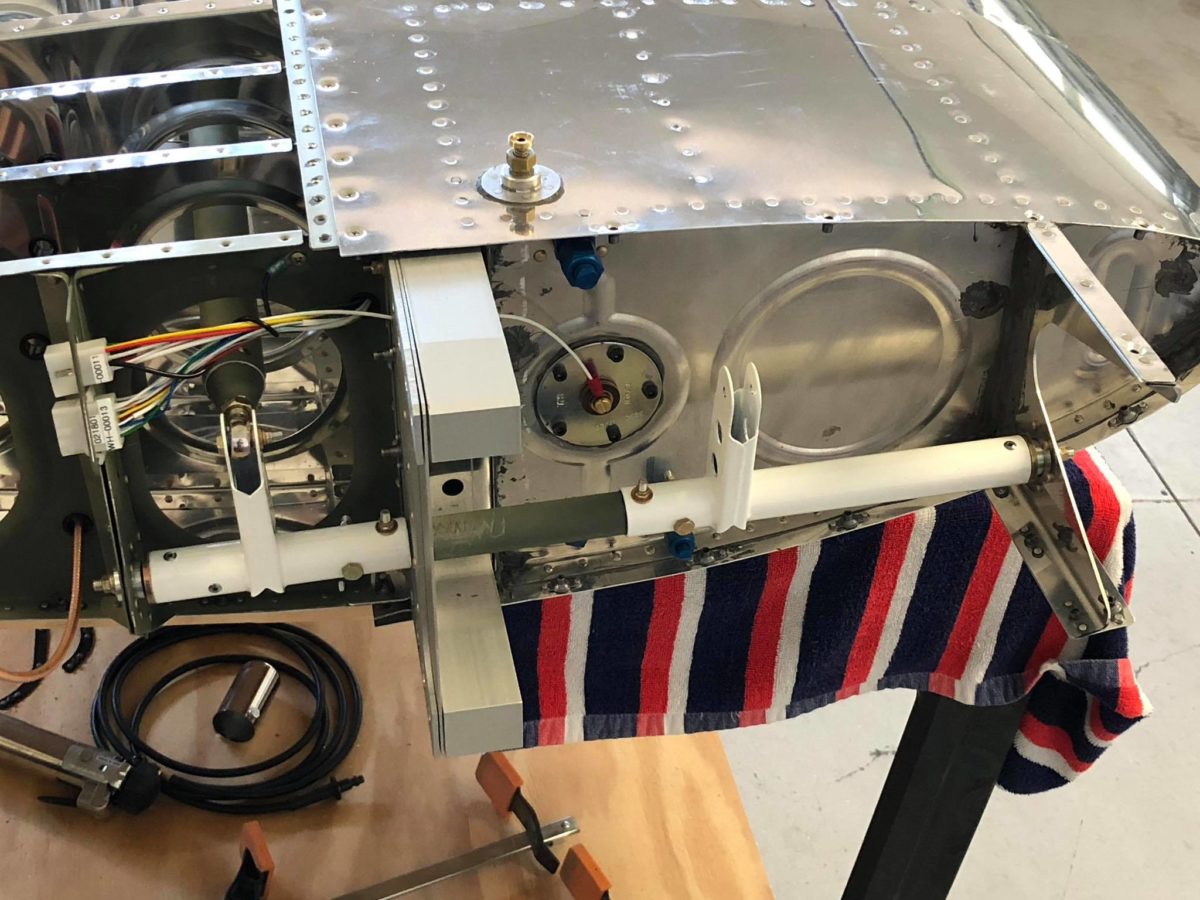

Forward and mid fuselage lower structures clecoed together.

Forward and mid fuselage lower structures clecoed together.

Yours truly with the work-in-progress.