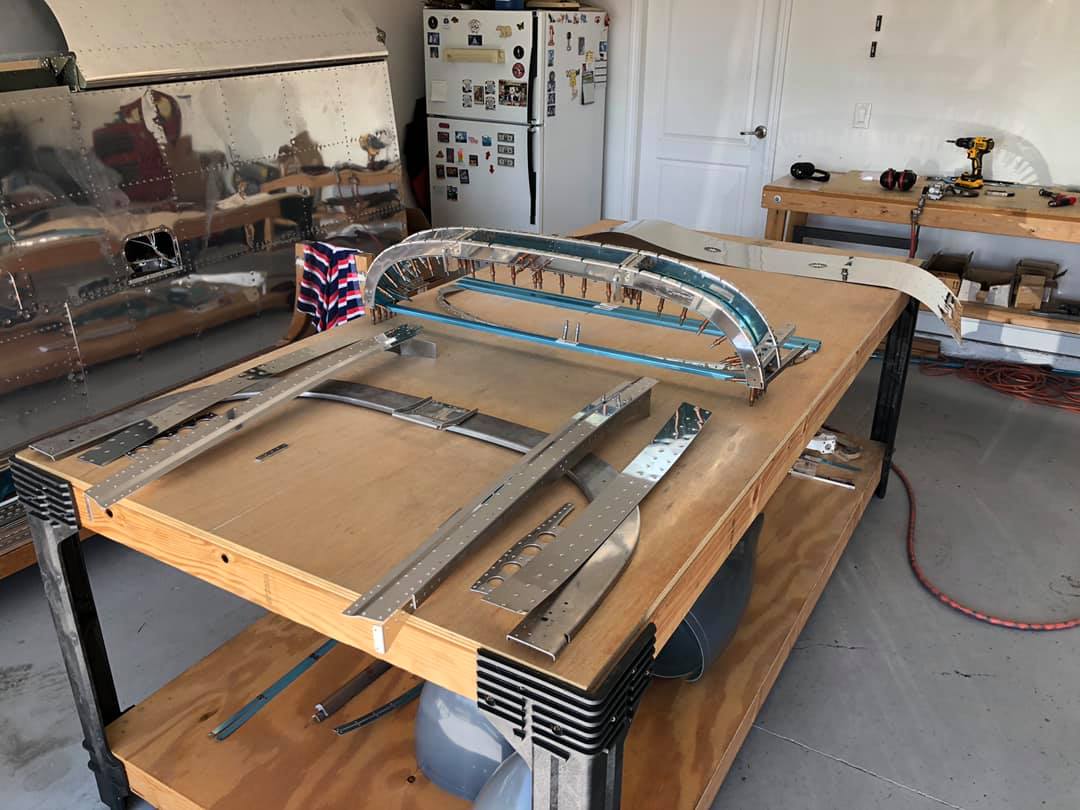

Canopy assembly close out clecoed for riveting.

Canopy assembly close out clecoed for riveting.

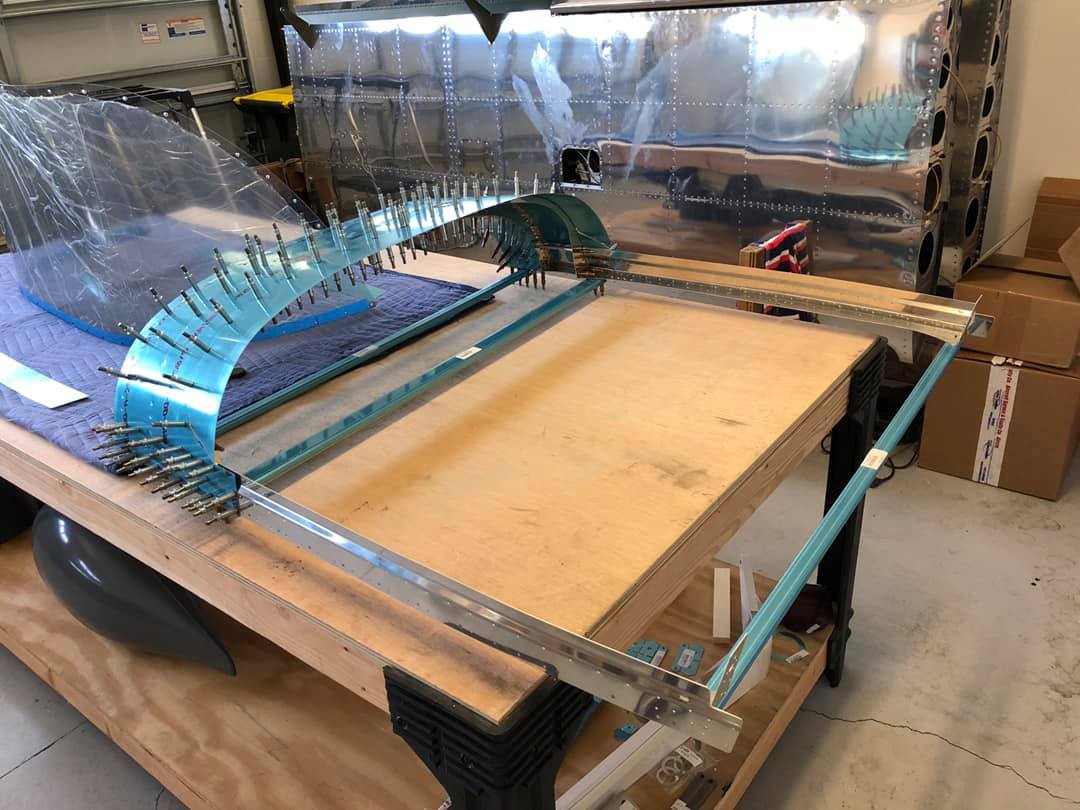

Canopy assembly close out riveting in progress. Stopping to check for twist every four rivets was a PITA, but better that than the alternative…

Canopy assembly close out riveting in progress.

Canopy assembly close out riveting complete.

Canopy rails clecoed for riveting.

Canopy rail riveting complete.

Aft canopy frame clecoed for riveting. Those three little AN426AD3 rivets on the lower outboard flanges of the frame were a BEAR to line up. I eventually got clecos into two holes per side and will just drill the third to fit.