Bottom cowl held in position by one Camloc on each side. My alignment marks (for vertical orientation) can be readily seen on each side. These were made prior to removing the upper cowling.

Bottom cowl held in position by one Camloc on each side. My alignment marks (for vertical orientation) can be readily seen on each side. These were made prior to removing the upper cowling.

Upper cowling replaced to double-check alignment of the sides.

Upper cowling replaced to double-check alignment of the sides.

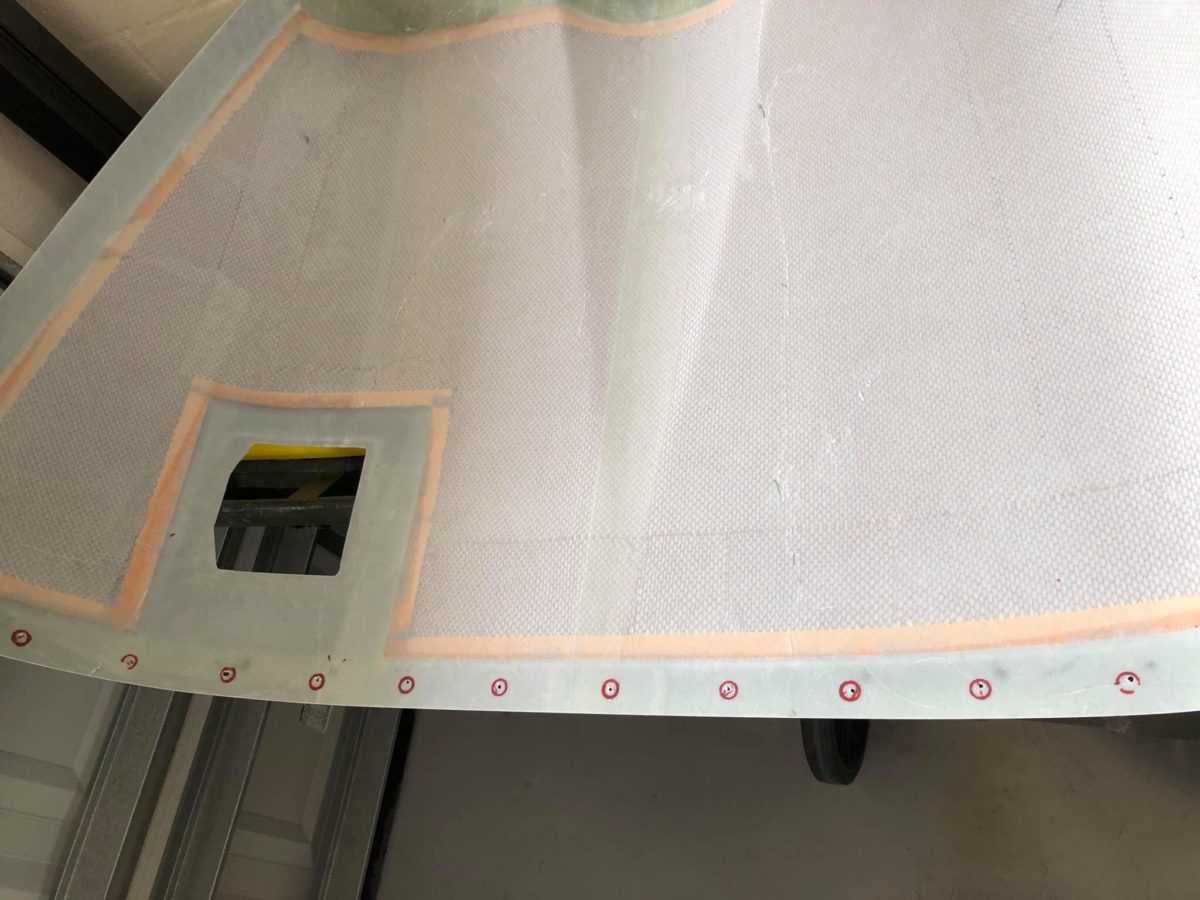

Bottom cowl Camloc receptacles riveted in place around the firewall.

Bottom cowl Camloc receptacles riveted in place around the firewall.

Bottom cowl Camloc grommets, retainers, and studs in place.

Bottom cowl Camloc grommets, retainers, and studs in place.

Bottom cowl in place and Camlocs adjusted for depth. Alignment marks still aligned, so that was good.

Bottom cowl in place and Camlocs adjusted for depth. Alignment marks still aligned, so that was good.

Complete cowling in place with all firewall Camlocs locked down. I’m fairly pleased thus far.

Complete cowling in place with all firewall Camlocs locked down. I’m fairly pleased thus far.

I couldn’t resist setting the spinner in place for a quick photo or two. Looks good!

I couldn’t resist setting the spinner in place for a quick photo or two. Looks good!