Rudder bottom fairing and taillight complete.

Spinner backing plates ready for installation.

Spinner screw holes drilled up to #19.

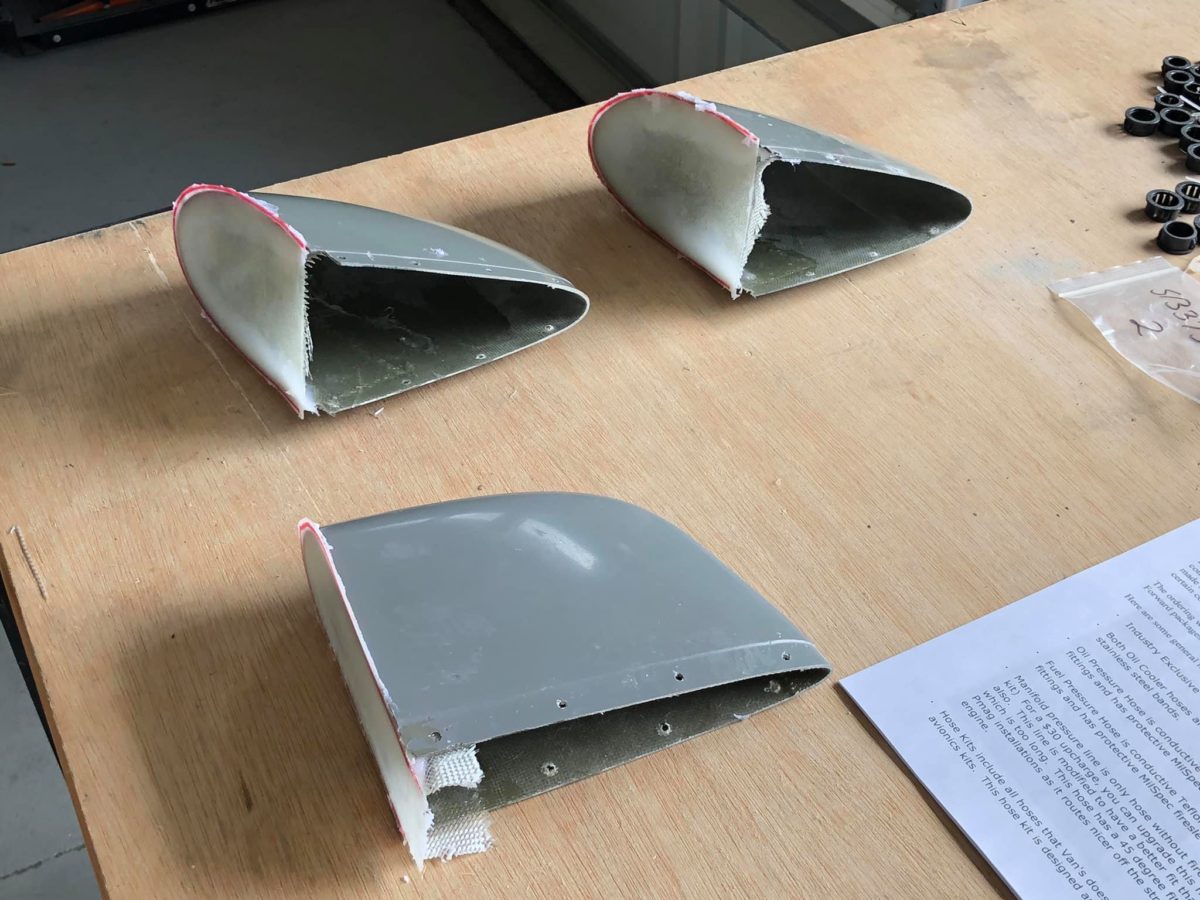

Empennage tip fairings and spinner gap fillers ready for installation.

The tip fairings are definitely not perfect, but they’re perfectly airworthy, so I’m fine with moving forward at this point. So far as I’m concerned, getting them perfect falls under paint shop surface prep – and they’ll be paid plenty for the work.

Left horizontal stabilizer tip fairing riveted in place.

Right horizontal stabilizer tip fairing riveted in place.

Vertical stabilizer tip fairing riveted in place.

Spinner plate assembly and front bulkhead drilled for nutplates and countersunk.